Electroninks Leads Industry with Total EMI Shielding Solutions Including Recon-Free Process

Recon-free innovation and new advancements in reliability create the industry’s most cost-effective, sustainable and scalable EMI shielding solution

AUSTIN, TX, UNITED STATES, December 1, 2025 /EINPresswire.com/ -- Electroninks, the leader in metal organic decomposition (MOD) inks for additive manufacturing and advanced semiconductor packaging, today unveiled its next-generation EMI shielding solution, setting a new standard for cost, performance, and reliability in advanced semiconductor packaging. Notably, the new Electroninks process involves a smaller tooling footprint and boasts a greater than 99 percent reduction in power and water use compared to conventional PVD and e-less metallization, also making it the most sustainable solution on the market.The solution is based on the company’s revolutionary EI-1200 ink series technology, which is engineered to directly metalize molding compounds, silicon and other relevant substrates in various packaging formats, including package-level, die-level, and wafer-level. However, the major advancements come from the addition of a recon-free process.

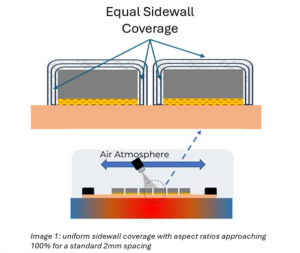

Electroninks’s MOD spray process offers major advancements in EMI shielding by enabling uniform sidewall coverage with aspect ratios approaching 100% for a standard 2mm spacing and the process can do recon-free (which depending on spacing and test vehicle design) can achieve up to 70 percent coverage. In both cases, a feat that traditional processes struggle to match. Critically, the ability to achieve sidewall coverage in such geometries enables manufacturers to eliminate the wafer dicing and reconstitution steps that are typically required to achieve sufficient spacing for traditional sputtered films. By bypassing these stages, Electroninks’s MOD process not only simplifies the overall packaging workflow but also boosts production throughput and reduces handling-related defects.

Silver is widely used in EMI shielding due to its excellent conductivity and high-frequency attenuation capabilities. However, it can be susceptible to surface sulfurization that can alter the film’s appearance when exposed to certain environmental conditions such as elevated temperatures, specific air qualities, or high-humidity tests like uHAST. While this tarnish is purely cosmetic and doesn't affect conductivity or shielding effectiveness, visible discoloration can erode customer trust, raise quality concerns in manufacturing and inspection, and create uncertainty for long-term reliability. Electroninks has worked with customers to develop solutions, such as the modification of its product chemistry or the addition of a black or clear overcoat, to completely eliminate this hurdle. When combined with the recon-free process, this creates the industry’s most advanced EMI shielding solution.

“The semiconductor packaging industry has long relied on sputtered EMI shielding layers, despite their cost and complexity,” said Brett Walker, CEO of Electroninks. “With EI-1207, we’re proving that MOD-based spray coating is not just viable; it’s technically superior, lower cost, more sustainable, and ready for high-volume adoption worldwide.”

At the core of EI-1207’s innovation is Electroninks’s proprietary MOD ink chemistry, a true solution, not a particle suspension, which enables superior film uniformity, low-temperature curing, and stable spray coating with no reconstitution required. The platform is already in use by leading OSATs, with production tool installations underway in both Korea and Taiwan.

Key technical advantages over traditional coating processes include:

* Up to 100% sidewall aspect ratio (vs. ~40% with PVD), eliminating the need for wafer dicing and reconstitution.

* Fully compatible with ultrasonic and pneumatic spray heads, enabling seamless integration into standard production lines.

* Simple thermal cure at 160°C, with tack-dry build-up during spraying—no complex vacuum equipment or multi-step sputtering required.

* Multi-head spray systems allow for higher throughput.

For the semiconductor industry, where throughput, yield, and sustainability are paramount, EI-1207 delivers tangible benefits:

* >99% reduction in power and water use compared to PVD.

* Up to 50% lower cost per package, based on third-party modeling by Savansys.

* Small equipment footprint allows for 8 spray coaters in the same floorspace as one PVD system.

* Higher throughput via parallel spray heads, easily scaling production volume.

* Material efficiency gains through optimized spray parameters that reduce silver waste—critical as silver remains the highest-cost input.

"From an engineering standpoint, EI-1200 series is a leap forward because it solves two of the biggest EMI shielding pain points in one stroke, uniform coverage and process complexity,” stated Sima Hannani, product director for Electroninks. “Improvements like achieving near-100 percent sidewall coverage or circumventing dicing and reconstitution steps aren’t just yield boosters; they fundamentally change how lines can be designed and run. Add to that a greater than 99 percent reduction in power and water usage, and you have a process that’s not only more precise but also inherently more sustainable. This is the kind of advancement that makes high-volume adoption inevitable."

By replacing capital-intensive and energy-hungry sputtering lines, EI-1207 positions Electroninks' customers to meet the performance and sustainability demands of 5G, RF-FEM, and SiP applications—without compromising shielding effectiveness. Testing confirms 60dB (1.2μm) to 80dB (3μm) shielding across 1–40GHz, with >30dB from 1MHz–1GHz.

For more information on Electroninks’ expanded portfolio and technical capabilities, visit www.electroninks.com.

###

About Electroninks

Electroninks Incorporated is a world-leader in the commercialization of advanced materials for electronics and semiconductor packaging. We have developed a full suite of proprietary metal complex conductive ink solutions and complementary material sets, thus accelerating time to market for both new innovations and drop-in manufacturing breakthroughs.

Electroninks’ metal complex inks – including silver, gold, platinum, nickel and copper – deliver higher conductivity, manufacturing flexibility, and cost-effectiveness. The company’s conductive inks provide reliable solutions for applications in printed circuit board (PCB) manufacturing, semiconductor packaging, consumer electronics, wearables, medical devices and more. We also partner closely with best-in-class equipment and integration partners to provide customers with a total ink and process solution with the ultimate goal of reducing the manufacturing costs and complexity.

To learn more visit: www.Electroninks.com

Contact@Electroninks.com

512-766-7555

Nicolia Wiles

Prime TechPR, LLC

+1 512-477-7373

email us here

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.